GIS 2

Sand Mining in Western Wisconsin

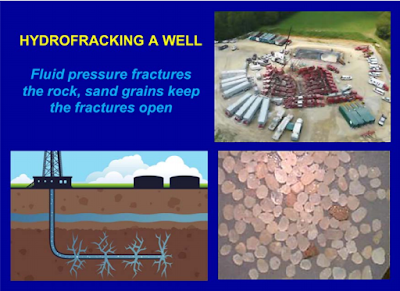

The mining of "frac" sand in Wisconsin for use in the extraction industry has become an extremely controversial issue throughout the state. Sand mined in Wisconsin is typically used for hydraulic fracturing (fracking) (Figure 2.). Fracking is a technique that is used to extract hydrocarbons such as oil or natural gas that could not otherwise be reached through conventional drilling/extraction methods (Wisconsin DNR).This method for extracting hydrocarbons has been around for 60 years. However, recent advancements in drilling technology have made extracting hydrocarbons with the use of fracking economical in regions where it was previously too costly to extract hydrocarbons. Overall, this post is intended to provide an overview of sand mining in Wisconsin. Several topics will be discussed including the issues and risks associated with sand mining in Wisconsin. An overview of how GIS can be used to investigate sand mining will also be discussed.

So what is sand mining in western Wisconsin, and why is frac sand mined here? The sand that is used in fracking must meet very specific qualifications. Frac sand must be extremely round and uniform in size (Sand Mining Facts ). The sand must also be pure quartz which makes the sand very hard. The specific strength and size specifications are what allow this type of sand to be used in hydraulic fracturing. Due to these specific specifications frac sand cant be found just anywhere. It just so happens that the correct sand can be found in certain sandstone formations throughout northwest and central Wisconsin. The specific sandstone formations where frac sand can be found includes several Cambrian formations (Wisconsin DNR). These Cambrian formations primarily include the Jordan, Wonewoc, and Mt. Simon Formations (Figure 1). The absolute best sand that can be used in the fracking industry is found in the Jordan formation. The Jordan formation is narrowly found in the southern part of Pierce County and western section of the Chippewa Valley.

Part of the controversy surrounding frac sand mining includes the methods used to actually mine the sand itself. The procedure involved to mine the sand includes several steps (Wisconsin DNR). First, overburden must be removed to expose the sand. Overburden can describe vegetation and topsoil that are variable in thickness. This step is generally performed by heavy machinery such as scrapers, bulldozers, and excavators. After the sand has been exposed it must then be excavated. Excavation is generally done by large front end loaders and excavators. However, a blasting step is sometimes required to allow the sand to be removed. Blasting involves the use of explosives to loosen the sand for excavation. Blasting has the potential to create dust emissions so steps are taken to reduce those emissions. One of the steps taken to reduce dust emissions involves the use of stemming material, which is used to back fill explosive bore holes. The last steps involved in the sand mining process involve the crushing and shipping of the sand. Many times the sand must be crushed at the mine site. Crushing is done to further sort the sand into the desired size. After the target sand has been separated the sand is then shipped to a sand processing plant to be processed into frac sand. It is important to include that after the mine is cleared of the desired sand, a reclamation process must occur to restore the area as best as possible. The reclamation process is typically an on going process that is designed to restore topsoil and integrity to the area so that the location can return to as much of a pre-mine state as possible.

Although steps are taken to mitigate the impact of sand mining. Environmental issues will often arise and can include the following (Wisconsin DNR). The first issue being that of air quality and pollution. Dust and chemicals involved in the handling and processing of the frac sand are often released into the surrounding environment leading to a decrease in air quality. Air quality issues typically arise in the areas around the mine and processing sites themselves.

Another sand processing activity than can have environmental implications is the washing of the sand at the processing plant (Wisconsin DNR). The process of washing and cleaning the sand involves the use of many thousands of gallons of water. In fact, the washing of the sand can use up to 3,000 gallons of water per minute. It should be added that there are efforts to recycle the water by putting it in holding ponds to be re-used. Despite efforts to re-use as much water as possible, processing plants can have great impacts on the local water tables. A sand processing plant can use up to 2 million gallons of water per day. This has the potential to significantly impact trout streams as well as personal home wells. There have also been many anecdotal references to a sand processing plants ability to severely disrupt local wells and water tables. It should also be added that various chemicals are used during the cleaning process which could have the potential pollute if not properly monitored, contained, and recycled.

An important impact that frac sand mining can have on the local area has to do with the transportation of the sand. Sand is often transported via dump trucks and semi trucks from the mine site to the processing plant. These heavy vehicles can decrease the longevity of road ways causing millions of dollars in repairs.

GIS (geographical information systems) software is an important tool involved in the monitoring of sand mining and processing. GIS can be used to monitor environmental impacts and local infrastructure. For example, GIS could be used to monitor regional wells and water table levels around sand processing facilities. The software could also be used to plan trucking routs and monitor the roads the trucks travel on. Databases could be generated in both instances that could be used for analysis purposes. GIS can also be used to map out where the sand mines should go, and provide information on the mines condition. The use of GIS software has the potential to save time and money, as well as increase environmental safety. These factors are ultimately beneficial to the companies and local communities involved in sand mining.

References:

Wisconsin DNR. (2012). Silica Sand Mining in Wisconsin. Retrieved from http://dnr.wi.gov/topic/Mines/documents/SilicaSandMiningFinal.pdf

Wisconsin Geological and Natural History Survey. (2012). Frac sand in Wisconsin. Retrieved from http://wcwrpc.org/frac-sand-factsheet.pdf

So what is sand mining in western Wisconsin, and why is frac sand mined here? The sand that is used in fracking must meet very specific qualifications. Frac sand must be extremely round and uniform in size (Sand Mining Facts ). The sand must also be pure quartz which makes the sand very hard. The specific strength and size specifications are what allow this type of sand to be used in hydraulic fracturing. Due to these specific specifications frac sand cant be found just anywhere. It just so happens that the correct sand can be found in certain sandstone formations throughout northwest and central Wisconsin. The specific sandstone formations where frac sand can be found includes several Cambrian formations (Wisconsin DNR). These Cambrian formations primarily include the Jordan, Wonewoc, and Mt. Simon Formations (Figure 1). The absolute best sand that can be used in the fracking industry is found in the Jordan formation. The Jordan formation is narrowly found in the southern part of Pierce County and western section of the Chippewa Valley.

Part of the controversy surrounding frac sand mining includes the methods used to actually mine the sand itself. The procedure involved to mine the sand includes several steps (Wisconsin DNR). First, overburden must be removed to expose the sand. Overburden can describe vegetation and topsoil that are variable in thickness. This step is generally performed by heavy machinery such as scrapers, bulldozers, and excavators. After the sand has been exposed it must then be excavated. Excavation is generally done by large front end loaders and excavators. However, a blasting step is sometimes required to allow the sand to be removed. Blasting involves the use of explosives to loosen the sand for excavation. Blasting has the potential to create dust emissions so steps are taken to reduce those emissions. One of the steps taken to reduce dust emissions involves the use of stemming material, which is used to back fill explosive bore holes. The last steps involved in the sand mining process involve the crushing and shipping of the sand. Many times the sand must be crushed at the mine site. Crushing is done to further sort the sand into the desired size. After the target sand has been separated the sand is then shipped to a sand processing plant to be processed into frac sand. It is important to include that after the mine is cleared of the desired sand, a reclamation process must occur to restore the area as best as possible. The reclamation process is typically an on going process that is designed to restore topsoil and integrity to the area so that the location can return to as much of a pre-mine state as possible.

Although steps are taken to mitigate the impact of sand mining. Environmental issues will often arise and can include the following (Wisconsin DNR). The first issue being that of air quality and pollution. Dust and chemicals involved in the handling and processing of the frac sand are often released into the surrounding environment leading to a decrease in air quality. Air quality issues typically arise in the areas around the mine and processing sites themselves.

Another sand processing activity than can have environmental implications is the washing of the sand at the processing plant (Wisconsin DNR). The process of washing and cleaning the sand involves the use of many thousands of gallons of water. In fact, the washing of the sand can use up to 3,000 gallons of water per minute. It should be added that there are efforts to recycle the water by putting it in holding ponds to be re-used. Despite efforts to re-use as much water as possible, processing plants can have great impacts on the local water tables. A sand processing plant can use up to 2 million gallons of water per day. This has the potential to significantly impact trout streams as well as personal home wells. There have also been many anecdotal references to a sand processing plants ability to severely disrupt local wells and water tables. It should also be added that various chemicals are used during the cleaning process which could have the potential pollute if not properly monitored, contained, and recycled.

An important impact that frac sand mining can have on the local area has to do with the transportation of the sand. Sand is often transported via dump trucks and semi trucks from the mine site to the processing plant. These heavy vehicles can decrease the longevity of road ways causing millions of dollars in repairs.

GIS (geographical information systems) software is an important tool involved in the monitoring of sand mining and processing. GIS can be used to monitor environmental impacts and local infrastructure. For example, GIS could be used to monitor regional wells and water table levels around sand processing facilities. The software could also be used to plan trucking routs and monitor the roads the trucks travel on. Databases could be generated in both instances that could be used for analysis purposes. GIS can also be used to map out where the sand mines should go, and provide information on the mines condition. The use of GIS software has the potential to save time and money, as well as increase environmental safety. These factors are ultimately beneficial to the companies and local communities involved in sand mining.

Figure 1. Above is a map of frac sand mines and processing plants throughout the state of Wisconsin A large cluster of sites can be seen in western Chippewa County. This map is provided by the Wisconsin Geological and Natural History Survey. Sand Mining Facts

Figure 2. Depicted is the general process of hydraulic fracturing. Also shown is the quartz sand used in the process of fracking. Hydrofracking and Sand Mining

References:

Wisconsin DNR. (2012). Silica Sand Mining in Wisconsin. Retrieved from http://dnr.wi.gov/topic/Mines/documents/SilicaSandMiningFinal.pdf

Wisconsin Geological and Natural History Survey. (2012). Frac sand in Wisconsin. Retrieved from http://wcwrpc.org/frac-sand-factsheet.pdf

No comments:

Post a Comment